Metal sheet thermal transfer film is widely used in modern industry and is suitable for products with different substrates including fabrics, plastics, ceramics, glass and metals. Its main application areas cover cosmetics, toys, electrical appliances, building materials, gifts, food packaging and other industries.

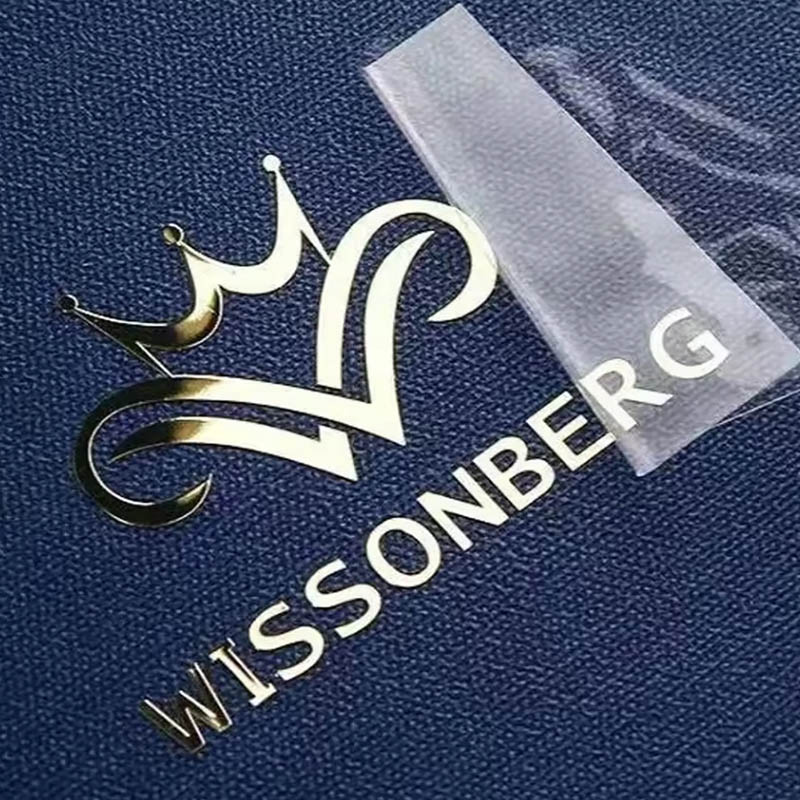

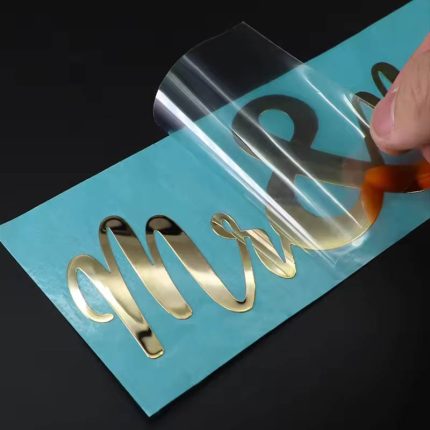

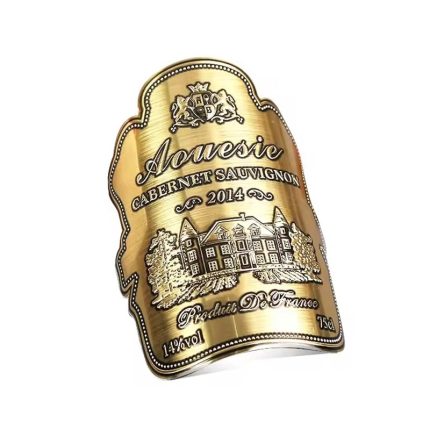

Metal transfer stickers use nickel alloy as the substrate. The colors are gold, silver, blue, red, black, white and other different colors, with multiple colors to choose from. The effect after pasting is three-dimensional and prominent. After pasting, the transparent film on the surface can be peeled off, and the content can be directly left on the object, thus achieving the effect of transfer. It is suitable for high-end gift boxes, packaging, mechanical equipment, instruments and other LOGO labels.

Equipment requirements

Foil stamping printer: working size is 60 cm wide, production speed is 6 square meters/hour.

Foil stamping and laminating machine: used to print white ink and foil varnish.

UV lamp: used to dry ink.

Metallic foil paper: used for laminating.

Laminating machine: used for laminating.

Metal UV Transfer Sticker Preparation

Materials: prepare metal sheets, PVC films and thermal transfer paper.

Transfer preparation: fix the transfer paper on the outer surface of the metal by vacuuming or gluing.

Transfer treatment: put the prepared metal into the thermal transfer machine, adjust the temperature and time for thermal transfer processing, and tear off the transfer paper on the metal surface after the transfer is completed.

Laminating treatment: use the laminating machine to wrap the PVC film on the outer surface of the metal sheet after the thermal transfer is completed.

Post-processing: pack the metal sheet after lamination.

Specific steps and equipment requirements

3D Adhesive Metal UV Transfer Label Sticker

Metal transfer sticker production process

1. Design the pattern

First, you need to design the pattern to be made. You can use various design software, such as Adobe Illustrator or CorelDRAW. When designing, you need to pay attention that the pattern needs to be monochrome and cannot have gradient or translucent effects.

2. Make the layout

Print the designed pattern on a transparent film, then place the film on the metal plate with a photosensitive coating and expose it with a UV exposure machine. After exposure, put the metal plate in the developer so that the unexposed part is dissolved to form a layout.

3. Make transfer paper

Place the layout on the transfer paper, heat and press it with a hot press, and transfer the layout to the transfer paper. This process requires good control of temperature and time to ensure that the layout can be completely transferred to the transfer paper.

4. Make metal transfer stickers

Place the transfer paper on the object to be made, heat and press it with a hot press, and transfer the layout to the object. It is also necessary to control the temperature and time to ensure that the layout can be completely transferred to the object.

5. Post-processing

The finished metal transfer sticker needs to be post-processed to ensure that the pattern can be permanently retained on the item. It can be cured using a UV light curing machine or protected with varnish.

Application fields and market prospects

Metal transfer stickers are widely used in personalized image printing of personalized T-shirts, magic stone paintings, porcelain tiles, pearlescent plates, etc., as well as personalized image production of various styles of coated cups. With the increase in personalized demand, the market prospects of metal transfer stickers are broad, especially in the fields of fashion and personalized decoration.

The production process of thermal transfer film for metal sheets has high technical requirements, which not only requires a deep understanding of the material’s properties, but also requires precise operating skills. In practical applications, selecting suitable thermal transfer film materials, optimizing transfer process parameters, and ensuring good transfer effects are key factors in ensuring the quality of the final product. At the same time, considering environmental protection and sustainability, using degradable or harmless thermal transfer film materials and optimizing production processes to reduce resource consumption and environmental pollution are also issues that need to be focused on in modern industrial production.